As the COVID-19 pandemic continues, Keck Medicine of USC employees and administrators are working extremely hard to respond to these rapidly changing circumstances. This ongoing series of stories will share the experiences of faculty and staff and their responses to the ongoing crisis. This week will focus on the work being done by Darryl Hwang, PhD, assistant professor of research radiology at the Keck School of Medicine of USC and assistant professor of biomedical engineering at USC Viterbi School of Engineering.

Answering the call

When Darryl Hwang got the text from Joseph Savoie, MHA, director of imaging services at Keck Medicine of USC, he immediately sprung into action. Savoie had reached out to Hwang, who is the director of Keck Medicine’s 4D Quantitative Imaging Lab, about creating an equivalent to the N95 respirator mask, an important piece of personal protective equipment (PPE) in high demand during the COVID-19 global pandemic.

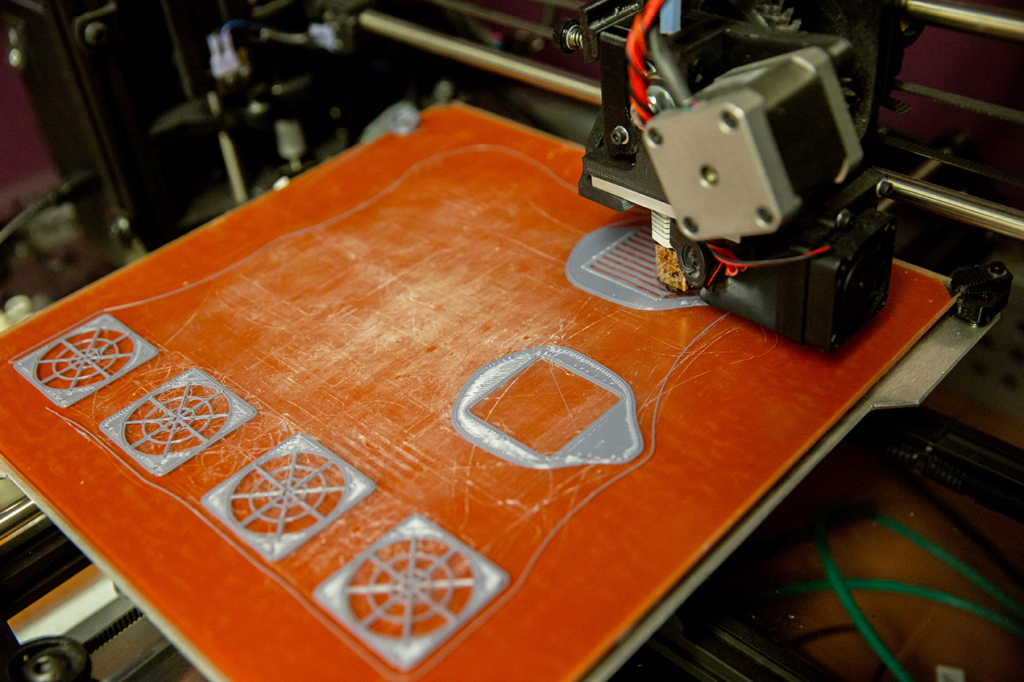

Using open source designs, which he modified to the specific needs of Keck Medicine providers, Hwang got to work. He has been utilizing not only the 3D printer in his own lab at Keck Hospital of USC, but also has brought together people from around the Los Angeles area to pitch in. A call for help on social media put him in touch with maker groups, individual makers and creative businesses with 3D printers. Hwang presented them with preliminary designs for pieces that could be easily printed to create a mask that is not exactly an N95, but could be used in case the N95s run out.

“As an engineer,” Hwang said, “It’s a weird feeling to make something you hope never gets used. But that’s the strange world we live in right now.”

Coming together to collaborate

Hwang also is working with USC Viterbi, USC School of Architecture, and the Fabrication Lab at the USC Iovine and Young Academy on PPE such as 3D-printed disposable face shields. They are also working on safe ways to extend the use of some equipment, and designs for other disposable pieces that will be necessary in the weeks and months to come. Hwang enlisted the help of a movie prop production house in Pasadena for their expertise in mold making in order to increase the speed of the production of parts.

“This has been the most creative work I’ve ever done as far as problem solving,” he said. “I’m just glad that we are able to contribute.”

— Amanda Busick